Additive Manufacturing

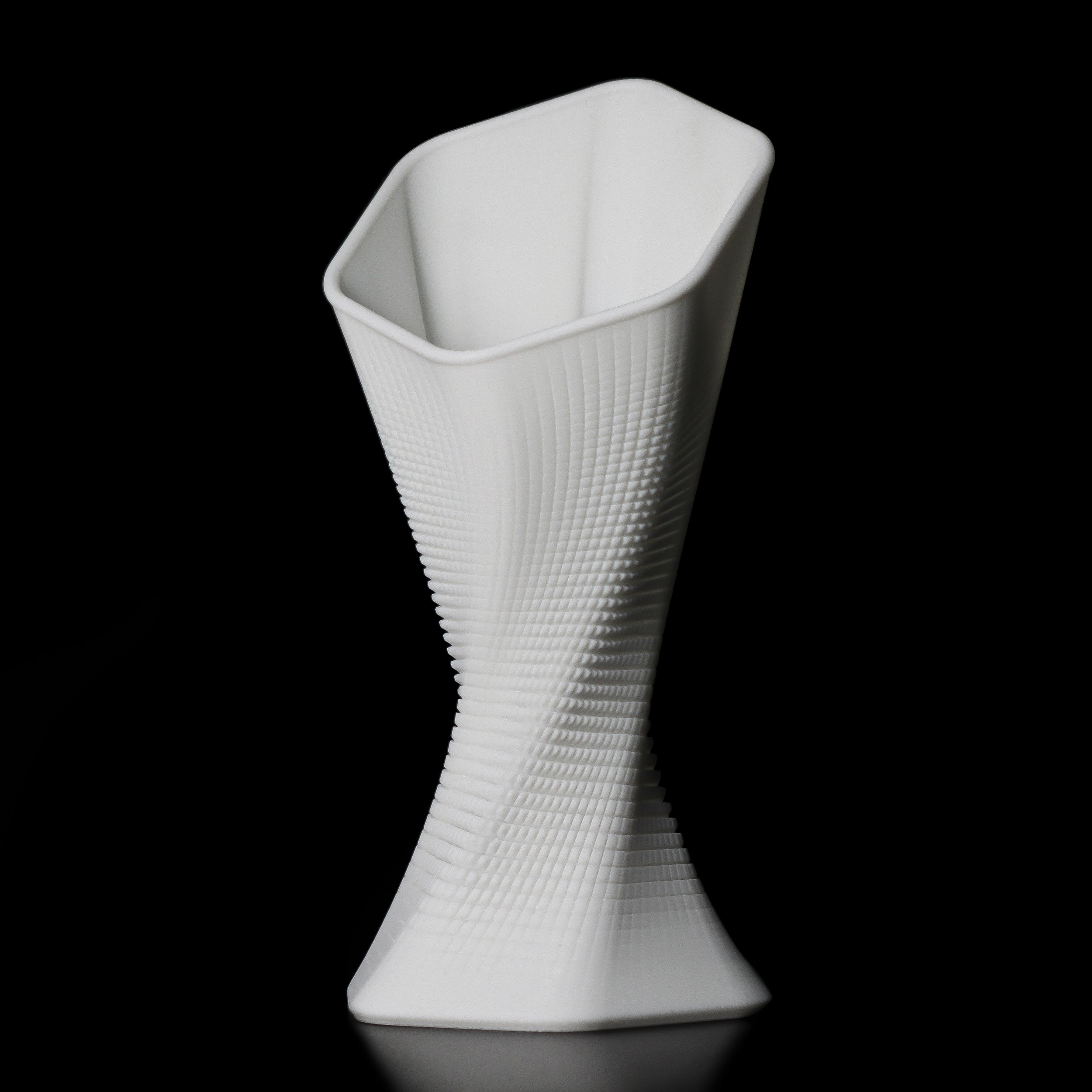

Additive Manufacturing, also known as 3D-Printing, unleashes the power of imagination by enabling design freedom and customization. It promotes environmental sustainability by minimizing material waste and reducing overall waste generation. Furthermore, the localized production enabled by 3D-Printing results in more sustainable manufacturing processes, with shorter supply chains and reduced transportation, leading to lower emissions and a positive ecological impact.

Especially for SP, it’s not just a tool to manufacture products but also a magic piece of technology that brings ideas and prototypes to life within a few hours.

In contrast to most companies that produce their products using FDM 3D-Printing, SP mainly works with the so-called stereolithography process (SLA). In this process, a liquid resin is cured layer by layer with the help of UV light to create the desired 3D shape. The object is then cleaned in an isopropanol bath.

The SLA process is much more complex than the FDM process, but in return offers by far the greatest level of detail of all 3D-Printing technologies due to layers in the µm range. Furthermore, by adding pigments, custom colors can be created.

Design Freedom

Minimal waste

Customizable design

Large material variety

New Collection

La Coupe

Le CORAIL